This utterly mesmerising beehive PC desk build took six months of painstaking labour and hypnotically simulates the bittersweet rise and fall of bee colonies in real time

A stunning fusion of advanced DIY engineering and exhausting hand-finished craft.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

"I've always admired bees, so I thought I'd build something that not only looks like a hive, but actually simulates one." So says YouTube channel Full Stack Woodworking, which set out to build a desk that simulates a bee hive. A simple enough concept, but let's just say this one spiralled a bit. And then some.

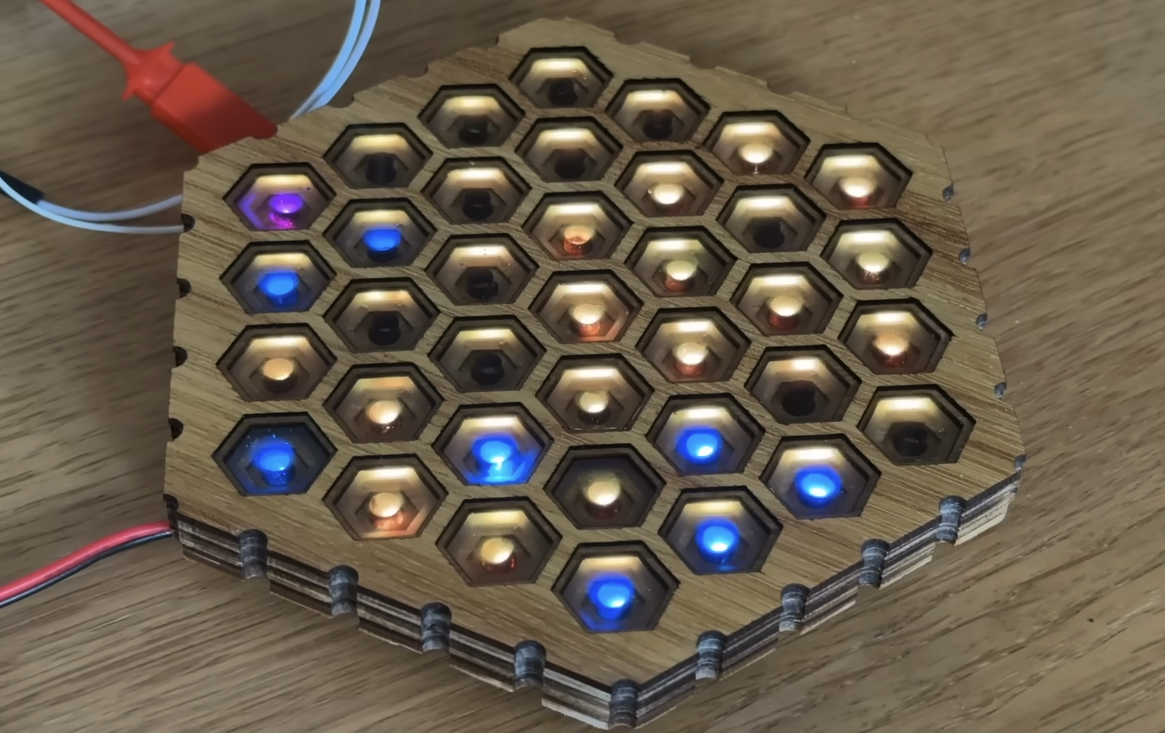

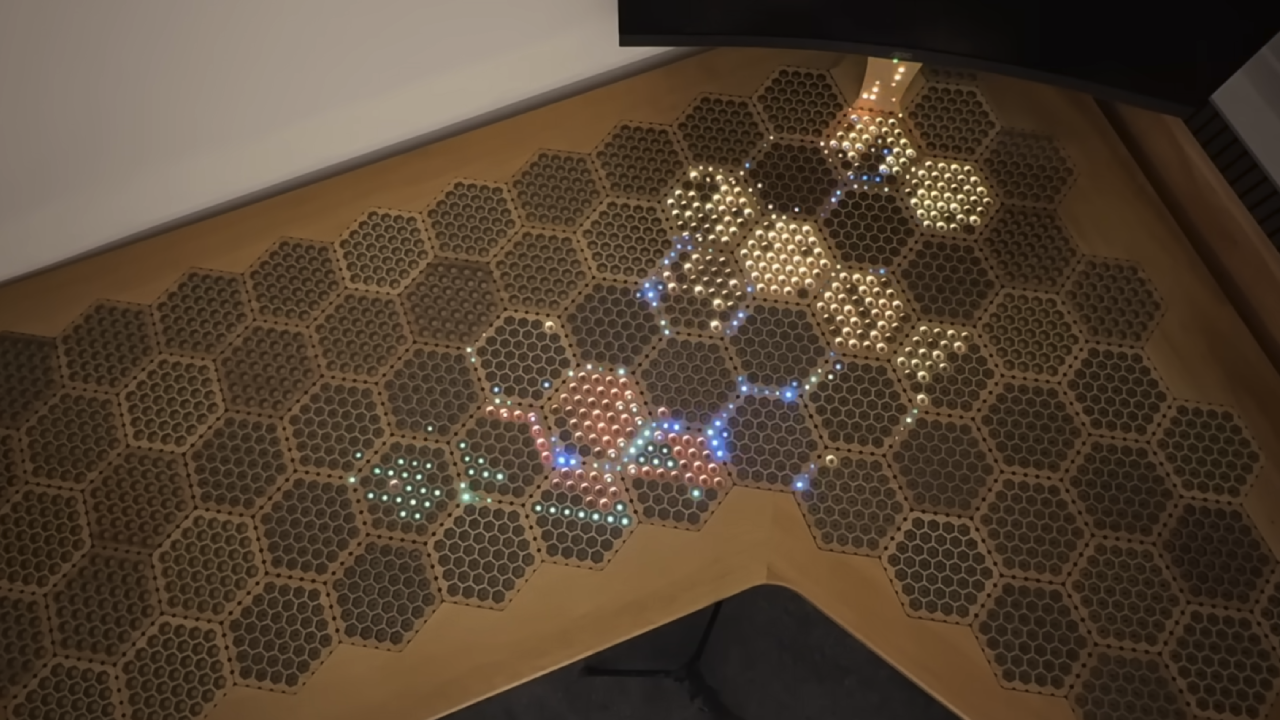

This incredible desk contains 74 hexagonal frames, 44 of which house 37 active RGB cells. Each multi-layered cell can display its status via perspex inserts and multiple LEDs (via Hackaday). Between the cells are pathways along which the bees travel, again with RGB lights.

All told, there are 3,745 LEDs. It's all controlled by software that Full Stack Woodworking also built. And the resulting bee hive simulation is utterly beguiling. But hold that thought, because this labour of love deserves describing.

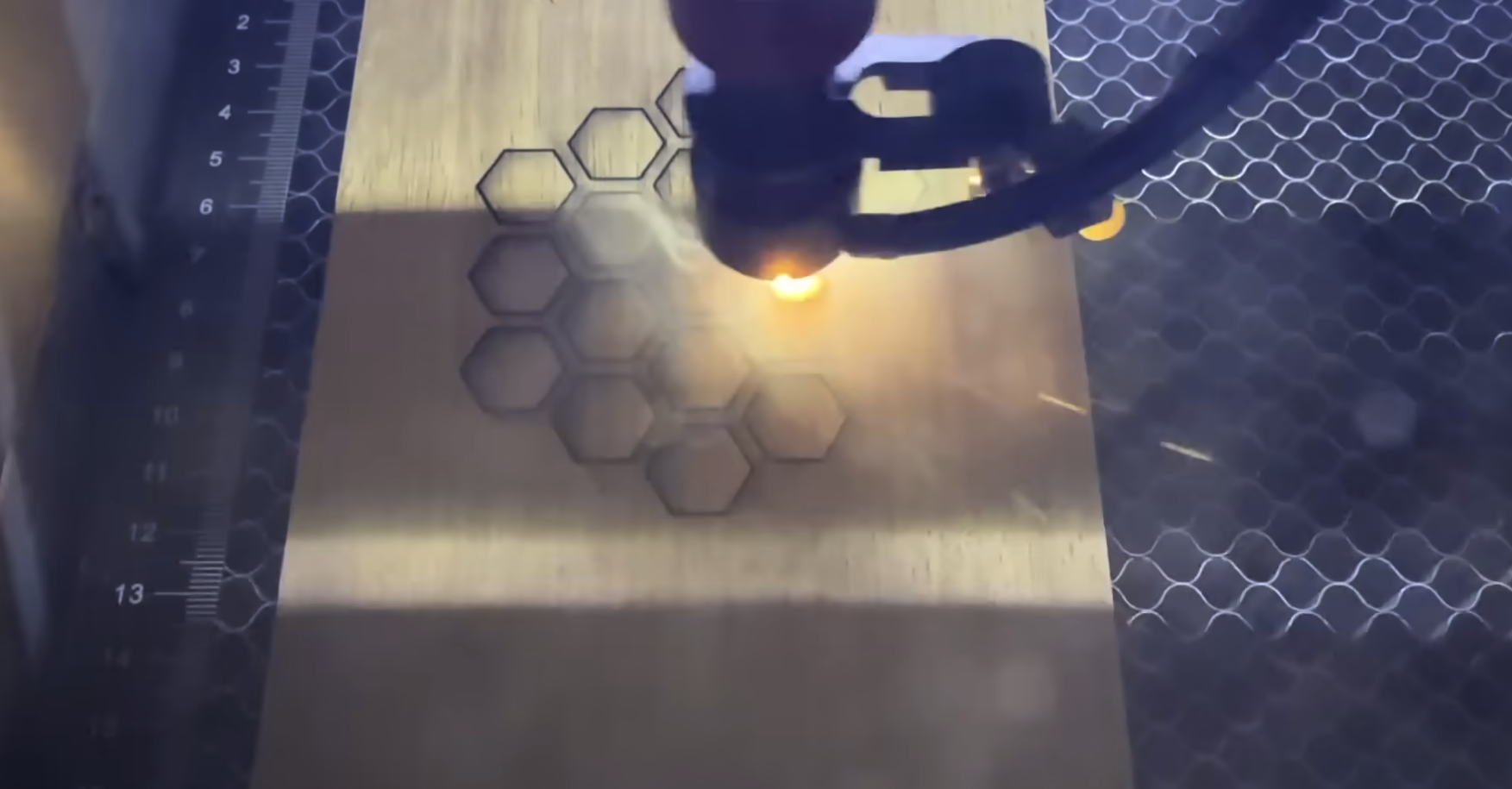

This is a hugely complex desk build. Just making the top layer of the cell frames from African hard wood was an incredibly involved process, requiring several steps to prepare uniformly thin strips of wood ready to be laser cut.

Full Stack Woodworking worked three sessions a day making the top hex frame layer—before work, after work, and before bed. And it took 25 days to get all 74 frames done. That's just for one small part of one element of this desk.

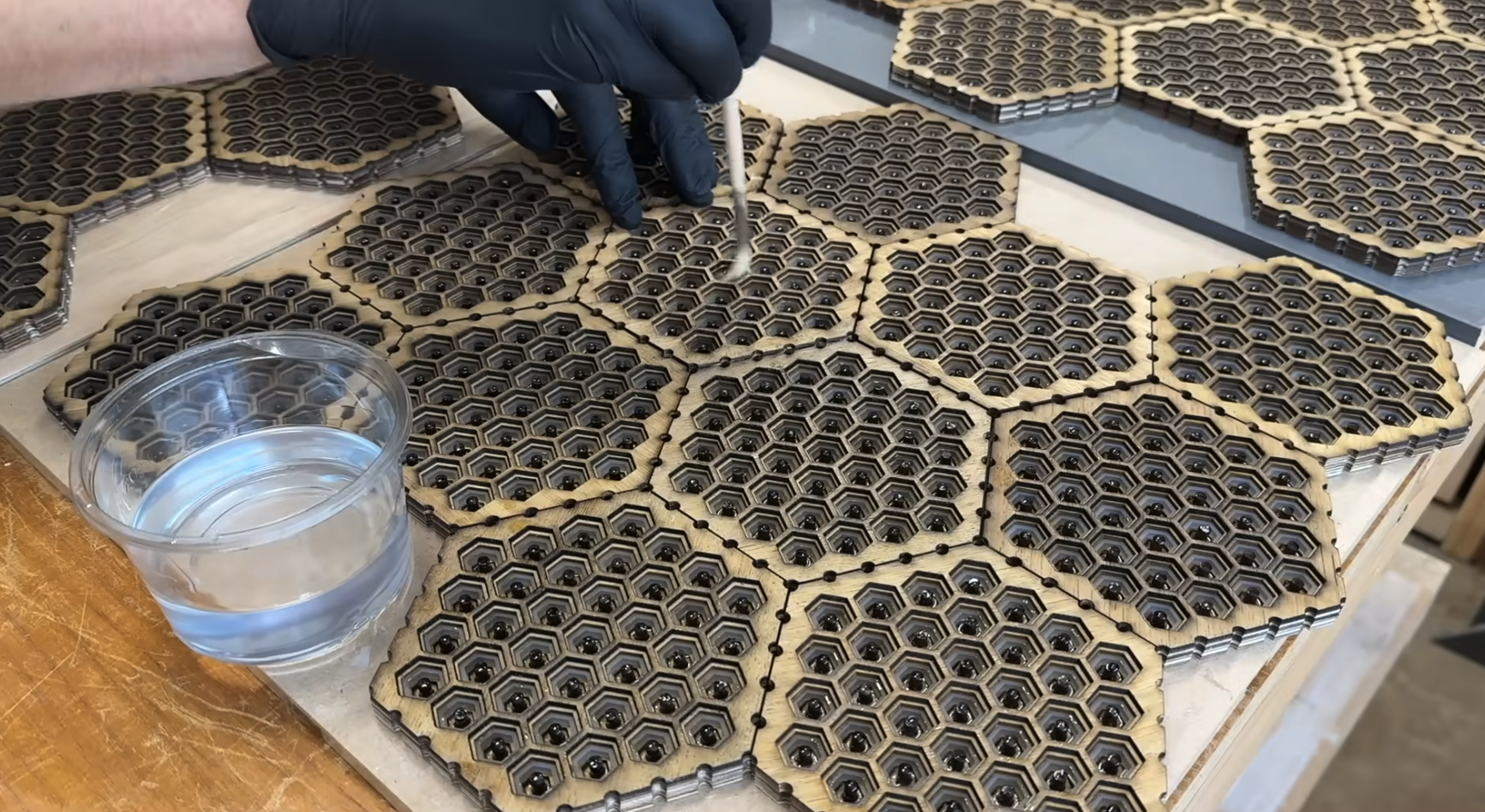

Inside each cell, an acrylic rod is used to transmit light and is glued in place by hand, all 1,628 of them. The cells are then filled with clear epoxy and sanded flat so the epoxy is level with the wood frame. The hex frames are built up of several laser-cut layers. In total 222 different operations were used on the CNC machines in getting the frames flat and all the same thickness.

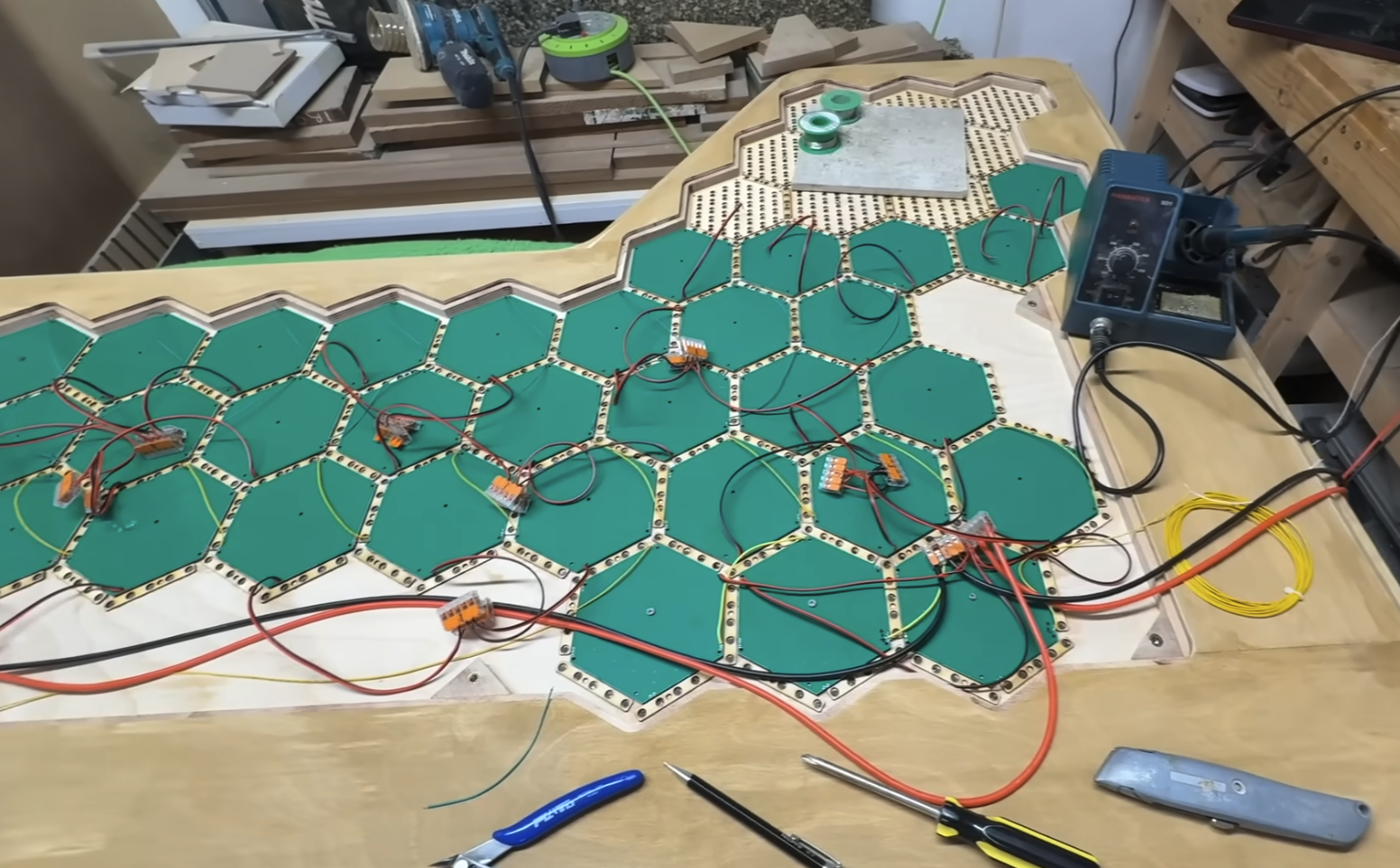

Of course, the LED lights needed custom-built PCBs with LEDs below each hex frame, plus another 130 PCBs for the bee pathways. To control all this, Full Stack Woodworking put together code in Python to run the hive. There are rules controlling each bee, including a queen laying eggs in empty cells. Attendant bees get food from storage to feed the queen. Nurse bees feed the eggs and after a certain number of days, they "hatch". Forager bees leave the hive to gather food and place it in storage cells. Bees age and progress through different roles.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

All of this is simulated with the various RGB LEDs. Each cell has an LED which activates when active and in use. Multiple colours from a second RGB LED indicate the cell's status and bee activity. The pathway LEDs likewise are RGB-lit to indicate the type of bee in transit.

Getting back to the physical build, the surround for the desktop neatly interfaces with the edges of the hexagonal frames and itself was fiendishly hard work. But of course, once the surround was in place, the hexagonal frames no longer fitted. So each hex frame had to be numbered and hand tweaked to achieve the final fit. Lining paper was used as spacers to standardise gaps between frames. Crikey.

Next up, holes for the LEDs below the cells were individually drilled out by hand using the guide and punch method. That's all 3,720 holes, including the pathway LED holes between the frames.

Then it's more light-conducting rods for the pathway holes, again fitted by hand, more clear epoxy over the top of those rods, more multi-stage sanding and levelling. Then it's time to fill those thousands of holes from below with round and square acrylic pegs, before they too are sanded back.

The bottom structure for the desk including mounting for power, cables and the Raspberry PI was the next step, all built around an old IKEA desk's metal frame. Again, all of this had to be custom-fit to the complex hex frame layout.

Next, spacers to sit below the hex frames into which the PCBs with LEDs slot were made. Oh and 130 spacers for the bee pathway PCBs, too. Then final sanding and polishing for the top side, 180 up to 4,000 grit, followed by a special epoxy polishing compound to achieve an almost glass like finish for the cells.

After that, it was on to wiring up all the electronics for the 44 active frames and 130 active pathways. That involved about 700 solder connections. Ouch. Frankly, the above is just some highlights of the incredible build process which took over six months.

The final result is a beguiling, organic display of bee hive activity. The simulation seems to run in something approaching bee real-time. So, almost as much patience is required to watch the hive develop as it took to build the desk.

Full Stack Woodworking says, "there is so much bee behaviour in real life that is complex and fascinating, distilling this into a simulation can never be more than a simplified copy. However, watching the hive at work is hypnotising."

On that we wholly agree. Each run of the simulation is different. Sometimes the hive prospers, sometimes it dies away quickly. It's all a thoroughly charming distraction from the usual daily onslaught of information overload and well worth a watch.

1. Best overall:

Minisforum AtomMan G7 PT

2. Best budget:

Minisforum Venus UM790 Pro

3. Best pure gaming:

Asus ROG NUC 970

4. Best compact:

Geekom AX8 Pro

5. Best looking:

Ayaneo Retro Mini AM02

6. Best iGPU for gaming:

Beelink SER9

7. Best for AI:

Framework Desktop

Jeremy has been writing about technology and PCs since the 90nm Netburst era (Google it!) and enjoys nothing more than a serious dissertation on the finer points of monitor input lag and overshoot followed by a forensic examination of advanced lithography. Or maybe he just likes machines that go “ping!” He also has a thing for tennis and cars.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.