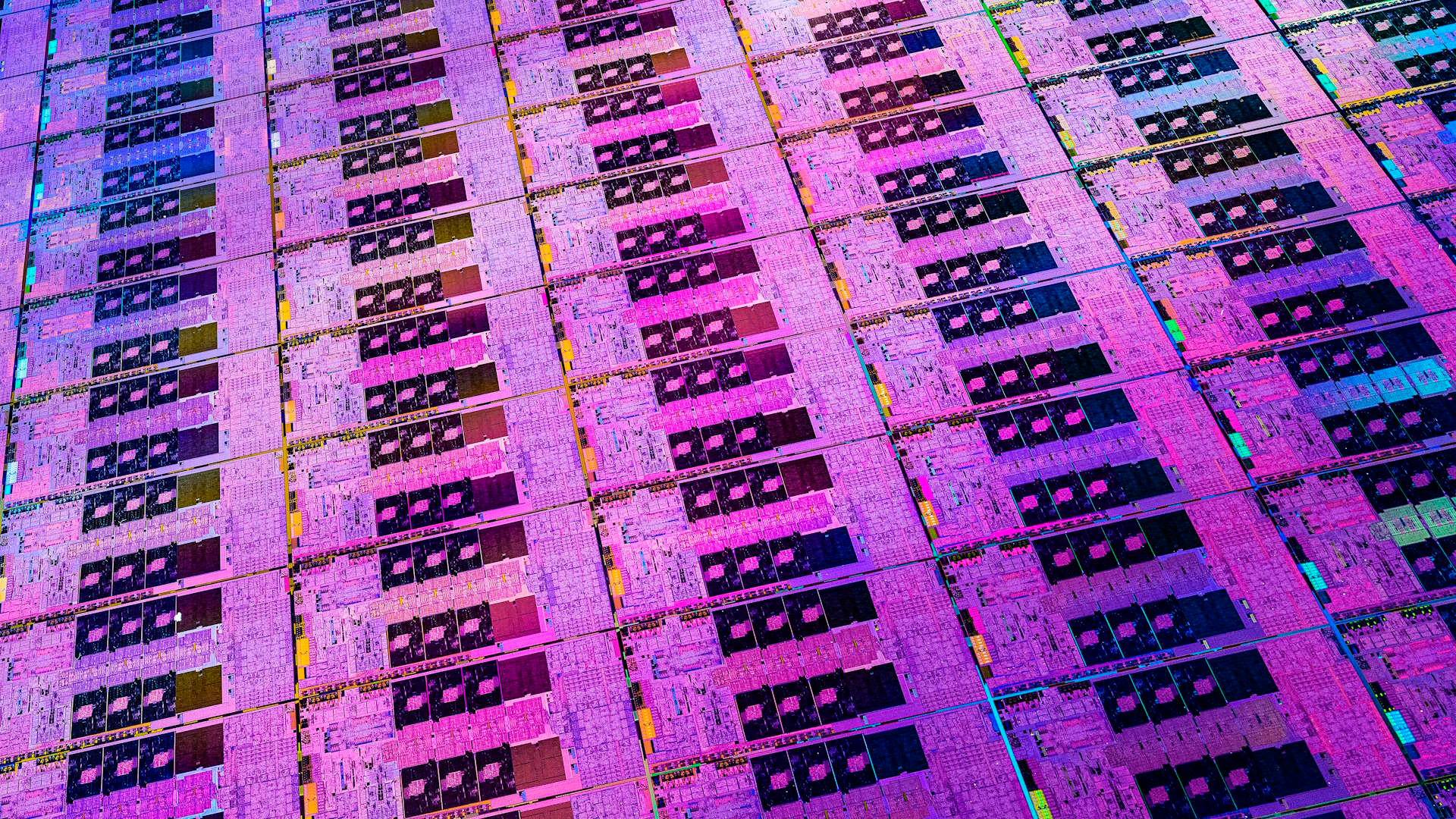

Intel's forcing its chip designers to pay market rates not mate's rates at its own fabs

Splitting the fab and products sides of Intel's business is both an effort in cost savings and enticing customers in to pay for its facilities.

Intel's announced a new switch to an "internal foundry model" which creates more separation between the products it designs and the fabs it uses to manufacture them. And there are some really good reasons for this. One, it creates a clear, secure distinction between the Intel that is designing new chips and the Intel that wants other people who also design new chips to come and manufacture them in its fabs.

The other reason is that it's going to force the designers of the various server and consumer CPUs and GPUs to interact with the company's manufacturing facilities as other fabless chipmakers do with external foundries. The upshot of that is that if they're getting charged market rates instead of mate's rates to use those facilities, the designers are likely to be less wasteful with testing and sampling during the pre-production process.

That will potentially save Intel up to $5 billion and could expedite the process of actually creating new processors.

It might also mean Intel's designers are maybe less ambitious in terms of how aggressive they are on densities of new process nodes, but that could be a good thing.

Intel's previous tardiness in getting new chip generations out the door has been linked to it tying processors to process nodes, and being overly ambitious on those new nodes. If, instead, it's more realistic in the design process it might stand a better chance of delivering on its promised targets.

We've already seen potentially good progress in Intel's target of five nodes in four years, and disconnecting chip generations from that process has certainly helped.

So, from the perspective of Intel's own chips this seems like a smart reorganisation of its business. Forcing its different departments to be a bit more responsible in terms of how it leverages its fabs and speedier in how it gets chips out the door.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

But it should also create more customer confidence in Intel's contract foundry business Intel Foundry Services. There has been some concern over whether customers might have issues giving up its designs for production if they are producing essentially competing chips to what Intel manufactures for itself. With this more distinct separation of the foundry group itself any customer IP is kept completely separate from the wider company.

In many ways it's a lot like how Samsung operates its own different business groups and contract foundry business.

The inevitable question that immediately arose when Intel announced the prospective separation, due to happen in January, is around whether this is simply a prelude to Intel splitting it up in order to completely separate its business entirely. Will Intel spin off a discrete foundry business and turn itself into a fabless entity?

That's certainly not the plan as it stands. David Zisner, Intel's chief financial officer, responded to the question in a Q&A after the announcement. "We think there’s a ton of benefit for having both, a product business and a manufacturing business combined. I think it enables better process technology over time."

Best CPU for gaming: The top chips from Intel and AMD

Best gaming motherboard: The right boards

Best graphics card: Your perfect pixel-pusher awaits

Best SSD for gaming: Get into the game ahead of the rest

"We think that our ability to use our internal customers as what we call customer zero to ramp volume on the new nodes is a benefit to the external foundry customers."

Essentially, companies coming in to use its fabs on a contract basis can be confident that Intel's already tested out its advanced nodes on itself.

"So, we don’t see this as a requirement to split the business," says Zisner. "We actually think quite the opposite. By doing this, it actually helps bring the businesses together in a more fulsome way."

Intel's certainly been putting its money where its mouth is recently, announcing major investments across the globe to get new facilities up and running in Germany, Israel, and Poland. And this reorganisation looks to be a smart one, too. Here's hoping it means Meteor Lake in mobile and Arrow Lake in desktop form do still arrive in good time and in good shape.

Dave has been gaming since the days of Zaxxon and Lady Bug on the Colecovision, and code books for the Commodore Vic 20 (Death Race 2000!). He built his first gaming PC at the tender age of 16, and finally finished bug-fixing the Cyrix-based system around a year later. When he dropped it out of the window. He first started writing for Official PlayStation Magazine and Xbox World many decades ago, then moved onto PC Format full-time, then PC Gamer, TechRadar, and T3 among others. Now he's back, writing about the nightmarish graphics card market, CPUs with more cores than sense, gaming laptops hotter than the sun, and SSDs more capacious than a Cybertruck.