Intel's creating its own contract foundry business to rival TSMC and help solve the chip supply crisis

Pat Gelsinger announces sweeping changes to put Intel at the centre of silicon manufacturing.

Intel's new CEO, Pat Gelsinger, has announced plans to transform Intel into a global leader in silicon manufacturing. It's going to go from focusing on producing its own chips, to using its fabs to produce chips for others as well. It isn't doing it purely for altruistic reasons either, as Intel sees the silicon manufacturing market as being worth $100bn by 2025.

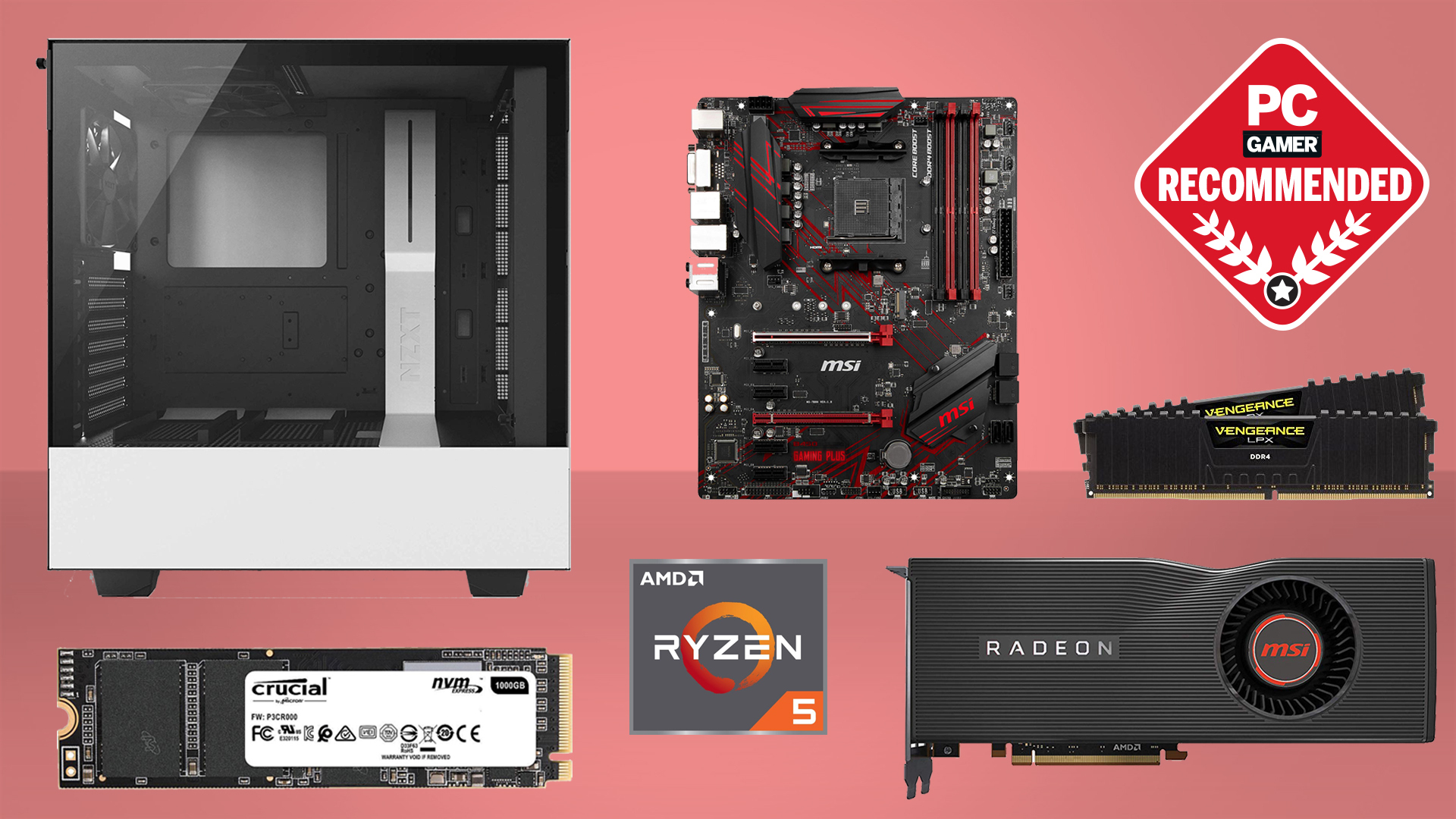

Best CPU for gaming: the top chips from Intel and AMD

Best graphics card: your perfect pixel-pusher awaits

Best SSD for gaming: get into the game ahead of the rest

Given the state of silicon demand right now, a major player like Intel offering out fab space to fabless companies has got to be tempting, even to traditional competitors likes AMD and Nvidia. If all goes as Intel's way, it could well be the case that your next AMD CPU could be produced by Intel and the same for your next Nvidia graphics card. Though that potential future is a long way down the line yet.

Intel is playing politics here as well, as it was keen to point out that much of the world's silicon is currently produced in Asia. According to Intel's figures, 80 percent of silicon is produced in Asia, with 15 percent produced in the US and only 5 percent in Europe.

Intel's looking to change that picture, and already has fabs in the US, in Ireland, and in Israel. The current reliance on production in Asia doesn't necessarily play too nicely with tech that's at the heart of national security. By expanding manufacturing away from Asia, it gives governments options they might not consider today.

Intel is putting its money where its mouth is and has already announced the expansion of its Octollio campus in Chandler, Arizona, with the plan for two new fabs. The upgrade to Fab 42, as it's known, accounts for a $20bn investment, and Pat Gelsinger suggested that there would be the following expansion announced shortly.

Intel also said that it's going to be using the likes of TSMC, Samsung, and Global Foundries to fulfil it's own manufacturing needs in the shorter term up to 2023 as well. This will help smooth over some of the manufacturing problems it has faced getting to 10nm, and it should help with the transition to 7nm too.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

Alan has been writing about PC tech since before 3D graphics cards existed, and still vividly recalls having to fight with MS-DOS just to get games to load. He fondly remembers the killer combo of a Matrox Millenium and 3dfx Voodoo, and seeing Lara Croft in 3D for the first time. He's very glad hardware has advanced as much as it has though, and is particularly happy when putting the latest M.2 NVMe SSDs, AMD processors, and laptops through their paces. He has a long-lasting Magic: The Gathering obsession but limits this to MTG Arena these days.