What's been going wrong for Intel?

Here's a brief summary of the trials and tribulations of the original chipmaking giant.

A quick look at Intel's financials would not suggest a company experiencing a turbulent patch. Across its many corporate groups, the company raked in $19.7bn in second-quarter revenue this year, up 20 percent over the same period last year. Clearly, the scuttlebutt of Intel's imminent demise is not entirely true to life. Yet, as ever, financial results do not tell the complete story.

Shares are hardly prophetic: Intel's most recent share price drop, which shaved 17% off its value, was in direct response to the company confirming that its 7nm process node would be delayed for six months. If you want an answer for how it ever got into its current position, you have to go back a little further.

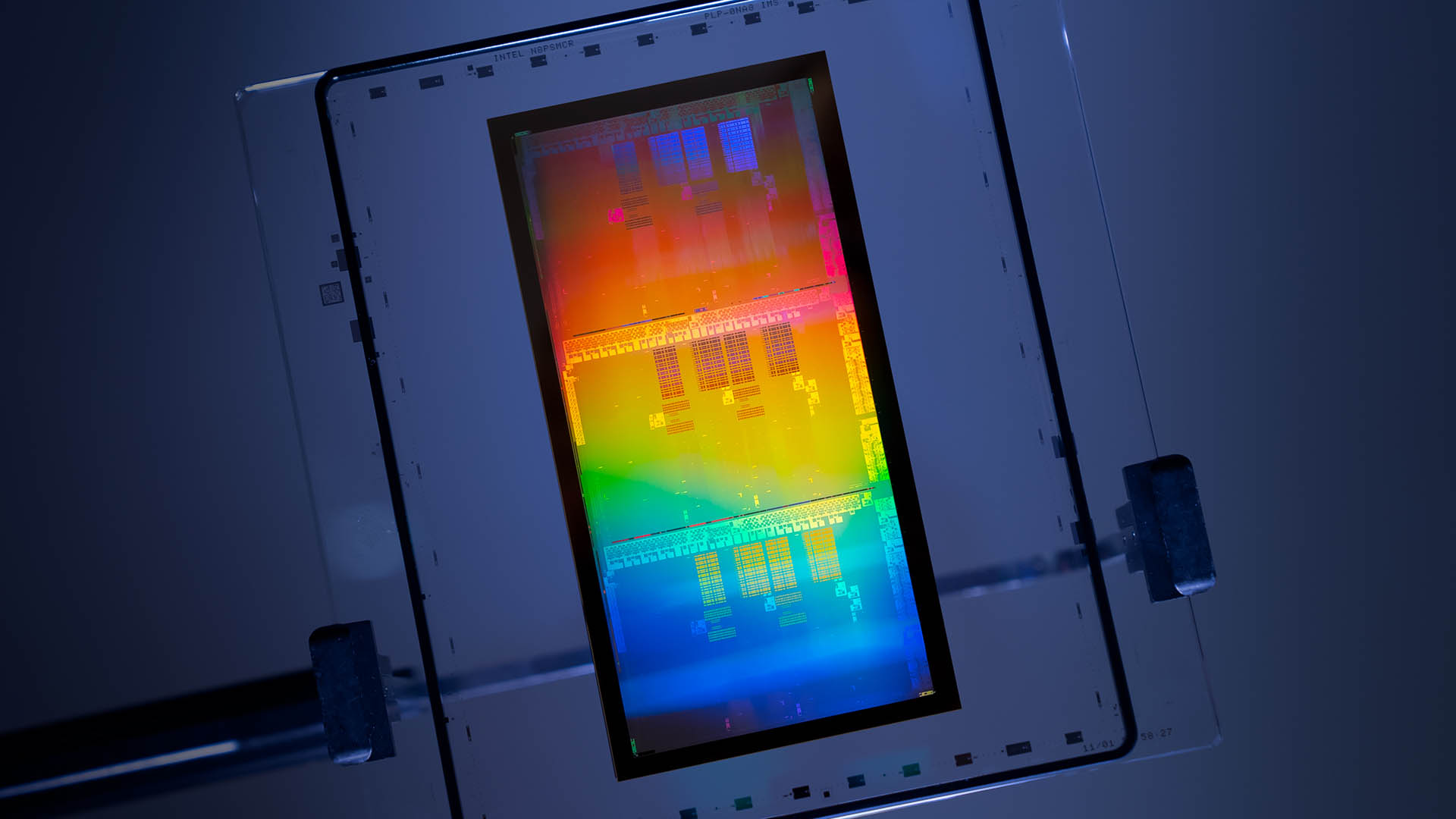

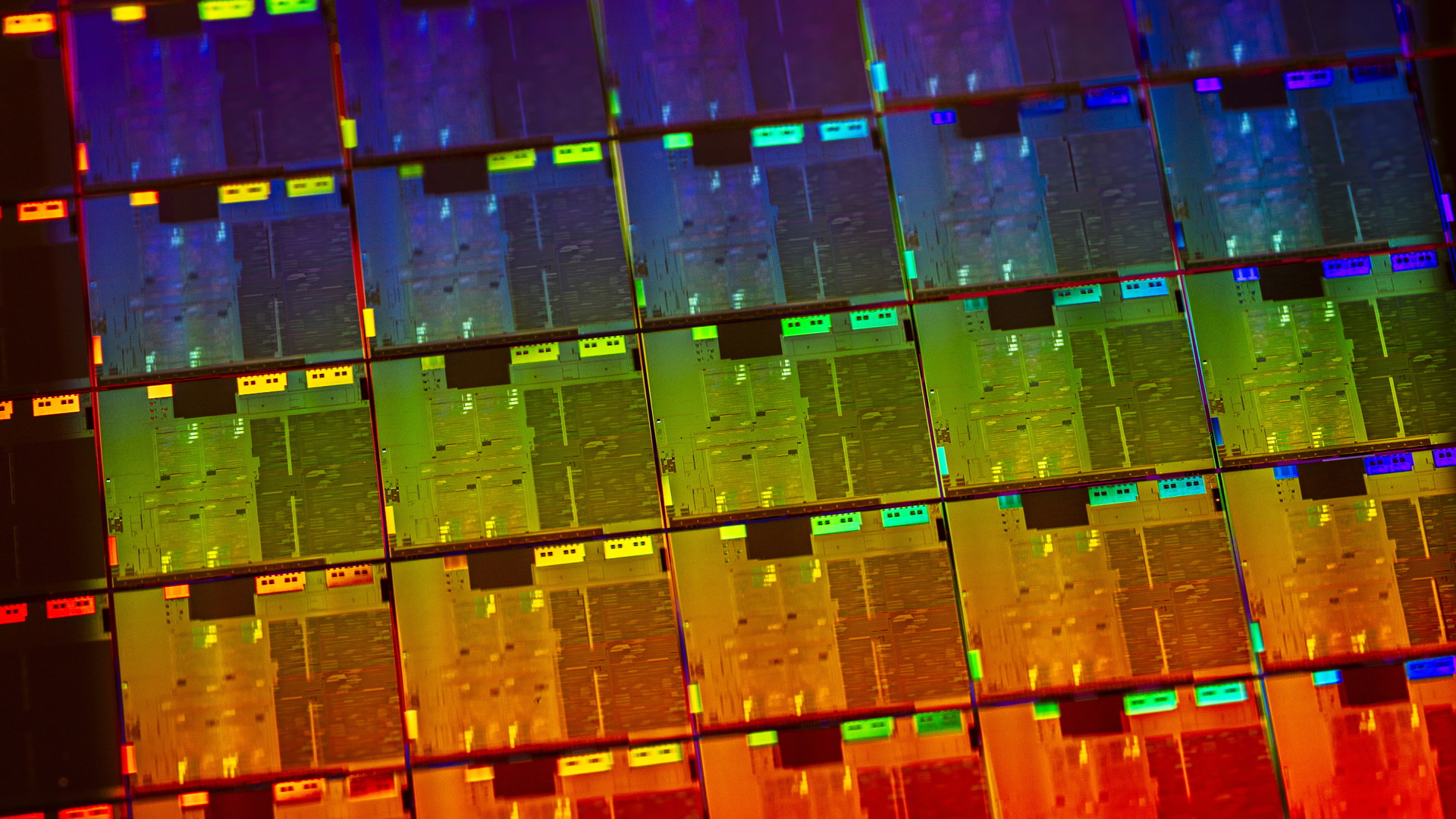

Intel is in a unique position among semiconductor giants: it's the only one that continues to own and operate its own fabrication plants, or fabs. These fabs are located in the US, Ireland, Israel, and China. It's what is known as 'vertical integration', essentially a company which owns its supply chain. Intel's employees are tasked not only with designing processors, but also manufacturing them using advanced lithographic processes—all the way down to the transistors at a nanometre level.

It's a position not shared by any other major player in the industry—AMD sold its fabs long ago and Nvidia never had any. They instead use companies such as TSMC, GlobalFoundries, and Samsung to produce chips on their behalf.

For a long time (more or less since the dawn of processors) this was Intel's ace in the hole: a world-leading manufacturing arm committed to fabricating its own processors. Yet it's also key to the conversation today as to why Intel's stalling—after years in the lead, Intel's hit some severe speedbumps.

Why is Intel stuck on 14nm?

The 10nm process node should've been Intel's crowning technological achievement. Intel employs thousands of excellent engineers, and by most reports they were all keen to make the 10nm process node far and away the most technologically advanced process on the planet. Yet for all its expertise—and never be fooled into thinking there's a lack of skilled people at the company—the 10nm node would never give Intel the leading edge it was aiming for.

The first 10nm product, Cannon Lake, a die shrink of the Skylake-derivative Kaby Lake architecture, was initially intended for release in 2015. Significantly delayed and demoted thereafter, in both scope and scale, the first and only Cannon Lake chip, the Core i3 8121U, was released in early 2018. You could hardly call it a launch, however. The chip was all but DOA: a dual-core processor with a base clock of 2.2GHz and a boost clock of 3.2GHz, and no integrated GPU because it just couldn't deal.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

The only 10nm processors currently available are found within 10th Gen Ice Lake laptops, which launched over a year after Cannon Lake flopped onto the scene. It is expected that this chip generation's replacement, Tiger Lake, will be announced in September. That should put Intel on a more steady 10nm launch cadence, at least.

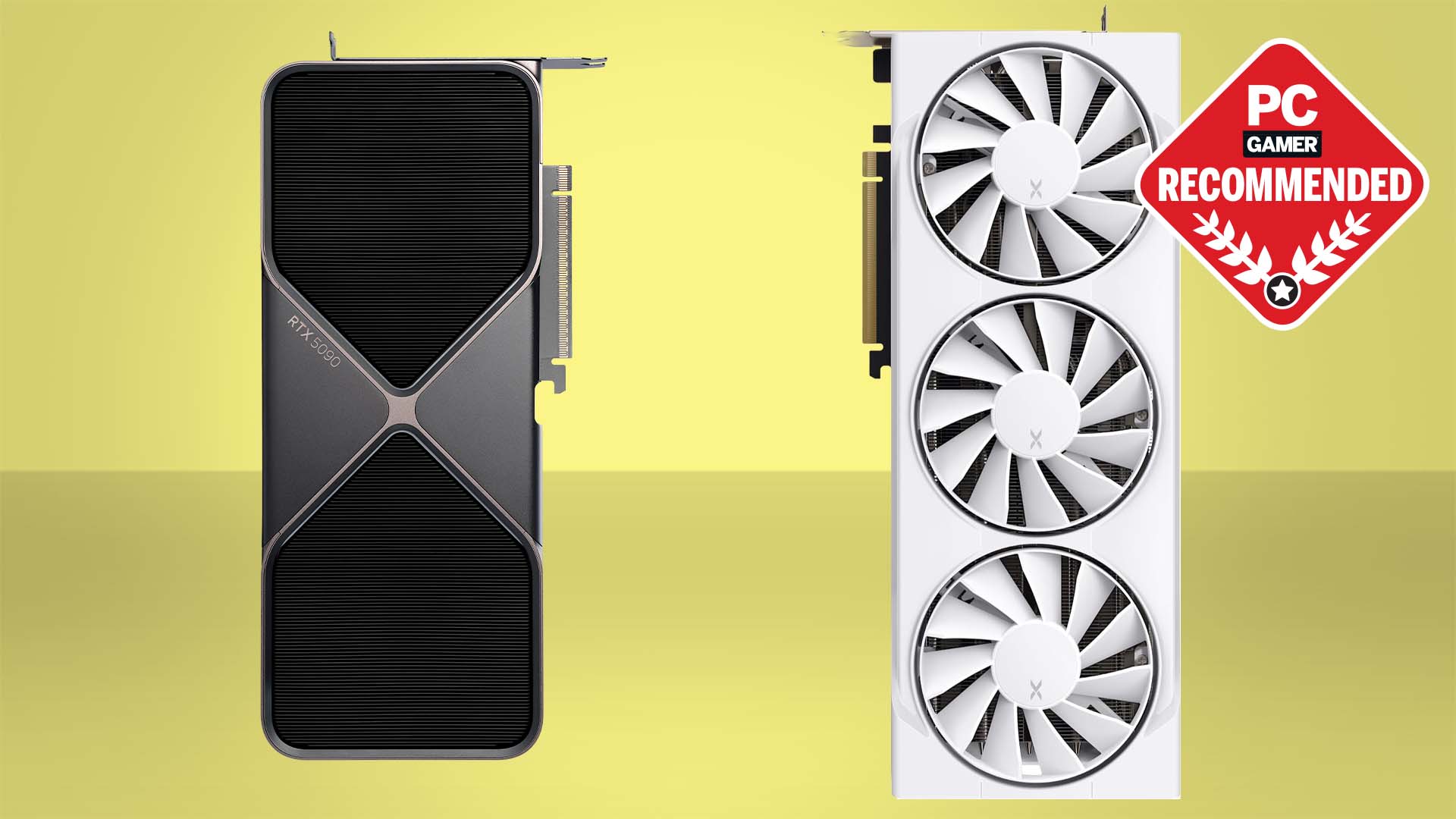

Best CPU for gaming: the top chips from Intel and AMD

Best graphics card: your perfect pixel-pusher awaits

Best SSD for gaming: get into the game ahead of the rest

Back to June, 2018, and Intel's CEO, Brian Krzanich, has just resigned due to the disclosure of a personal and consensual relationship with an Intel employee. His replacement, ex-CFO Bob Swan, would be left with the unfortunate job of penning an open letter to Intel's partners, suppliers, and shareholders confronting growing rumours of a supply shortage at the company shortly thereafter.

"The surprising return to PC TAM (total addressable market) growth has put pressure on our factory network," the open letter reads. "We’re prioritizing the production of Intel Xeon and Intel Core processors so that collectively we can serve the high-performance segments of the market. That said, supply is undoubtedly tight, particularly at the entry-level of the PC market."

Acutely affecting the company's most up-to-date and high-yield process, 14nm, which makes up the best CPUs for gaming from Intel to this day, Intel's supply shortage was believed to have stemmed from congestion caused by the 10nm slowdown and as more products were transitioned over to the up-to-date 14nm process.

That included the motherboard chipsets, which have historically been kept on an older node to avoid such bottlenecks.

Intel had reached an inflection point: when its usual stony-faced approach to rumour and speculation would no longer suffice and it would have to, to some degree, own the challenges it now faces.

As I mentioned before, these challenges are unique to Intel among the world's largest chipmakers because it owns and operates its own fabs. Whereas AMD learned to live without its own manufacturing arm ("Real men have fabs", AMD founder Jerry Sanders would say, prior to his successors selling off all of AMD's fabs), and Nvidia never had fabs to begin with (and has since become the most valuable US chipmaker), Intel has been able to sustain its in-house manufacturing division with a high degree of success all these years.

The 10nm process tarnished an otherwise near-spotless record for Intel's manufacturing arm.

Supply is undoubtedly tight, particularly at the entry-level of the PC market

Bob Swan, Intel CEO

However, the 10nm process delay would not only strain supply for the operational 14nm process, but also halt the roll out of architectures, such as Ice Lake, that are intrinsically linked to the advanced lithographic process, and damage the company's carefully curated and seemingly irrefutable reputation as the biggest and best.

Intel Ice Lake server chips are still MIA, and 10nm desktop processors that are best suited for us PC gamers are unlikely to make an appearance until 2021 with Alder Lake.

Yet Intel could not stand idly by and wait for 10nm to come to fruition before moving onto developing its successor, 7nm. Its only major x86 rival, AMD, has been evidently resurgent since the release of its Ryzen and EPYC processors. Reliant on pure-play foundry giant, TSMC, who is pressing ahead with process nodes well into the low single digits, AMD is on course for a much swifter adoption of the most advanced nodes.

Node naming is actually a rather fickle affair. What does 7nm mean in relation to 10nm or 5nm? Not much. Intel is keen to do away with subjective naming standards—unsurprisingly, too, as it's the company's 10nm and 7nm process nodes that are often unfairly compared to the competitions' in name alone.

Read on about the push for a universal density metric for semiconductors.

The 7nm process node was planned to go-ahead for launch in 2021. However, during a recent earnings call—the catalyst for Intel's recent bout of bad news—Bob Swan confirmed that a known issue present in the 7nm process was causing errant yields lower than expected. Thus Intel would be delaying the process until 2022.

It is reported that Intel will also seek out TSMC for production of a large quantity of chips. The move, while not yet confirmed, has led to speculation that Intel would seek out further third-party support going forward, bolstered by recent comments from CEO Swan.

"The extent that we need to use somebody else’s process technology and we call those contingency plans, we will be prepared to do that. And if we do, there are lots of moving parts," Swan said during a recent earnings call.

These delays, initially the 10nm process node and most recently the 7nm process node, have been from which most of the company's headaches have stemmed. However, the loss of Apple to Arm, pressure from AMD, and Nvidia's ambitions to rule over the datacentre and machine learning workloads with highly-parallel GPUs, have only served to compound its symptoms.

In response to growing pressure on its technology division, Intel's CEO Bob Swan announced changes to the company's top brass. Dr. Murthy Renduchintala left the company on August 3, 2020, and his position of overall authority over the Technology, Systems Architecture, and Client Group would be dissolved and separated into smaller divisions—all of which would report to Swan directly.

The impact of which will surely not be seen by consumers for some time.

I am not writing Intel's obituary, however—reports of Intel's death have been greatly exaggerated, yada yada. The company has continued to push the technological boundaries of processor construction for years, and whether you appreciate its consumer-facing strategy or not, it will more than likely continue to do so in the face of challenging competition.

If there's one thing money can buy, it's great engineering talent. And, if you recall, Intel isn't short of either of those.

Jacob earned his first byline writing for his own tech blog. From there, he graduated to professionally breaking things as hardware writer at PCGamesN, and would go on to run the team as hardware editor. He joined PC Gamer's top staff as senior hardware editor before becoming managing editor of the hardware team, and you'll now find him reporting on the latest developments in the technology and gaming industries and testing the newest PC components.