Have a look at how Gigabyte builds a gaming motherboard from start to finish

This nifty factory tour shows what goes into making a motherboard.

Building a PC isn't overly difficult, and it's easy to take for granted that the parts, if compatible, will simply work when plugging them in and firing it all up. These are rather complex pieces of technology, though, and the best gaming motherboards are tasked with bringing everything together. If you've ever wondered how companies turn these slabs into functioning PCBs, you should take a look at this factory tour.

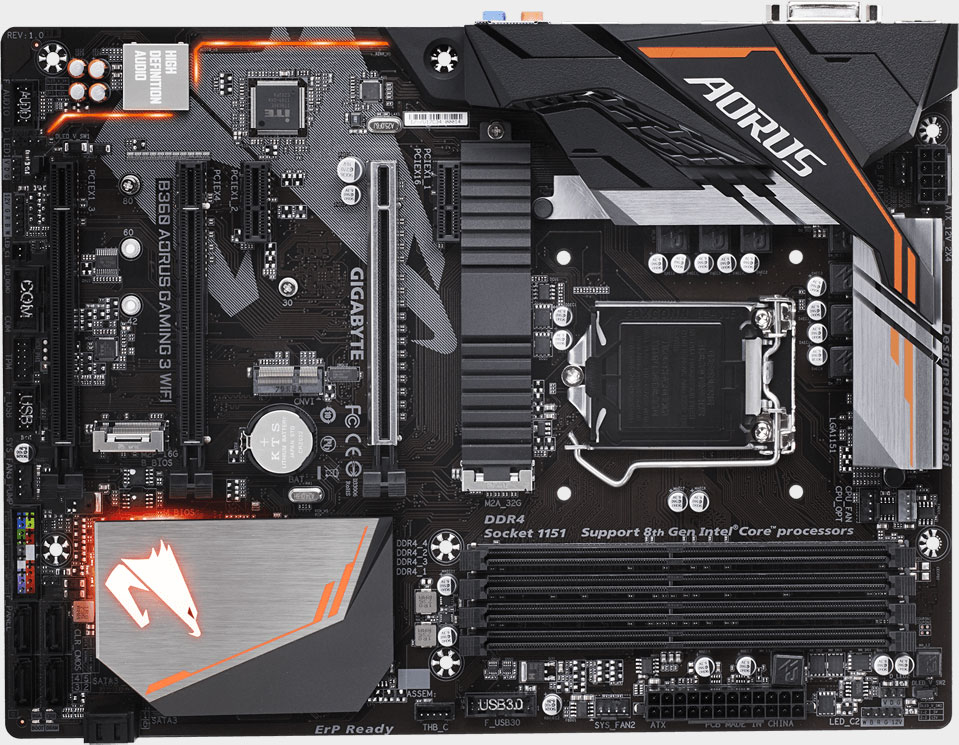

Steve Burke at Gamers Nexus popped over to one of Gigabyte's factories in Taiwan and filmed the different steps of making a motherboard, from start to finish. The nearly 14-minute video follows the construction of a B360 Aorus Gaming 3 Wifi, from attaching the BIOS and applying thermal paste, to inspecting every square inch. Have a look:

It's a fairly standardized process, and not surprisingly, considering that Gigabyte churns out so many boards. According to Burke, Gigabyte builds around 200,000 motherboards per month, and the same number of graphics cards.

The initial process takes around 30 minutes, though that doesn't include the application of PCIe slots and CMOS batteries, which are applied manually, and the heatsinks. There's also a testing process once it's all put together. All told, around 30 percent of the assembly is automated, and the rest done by hand.

Check it out when you get the chance.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

Paul has been playing PC games and raking his knuckles on computer hardware since the Commodore 64. He does not have any tattoos, but thinks it would be cool to get one that reads LOAD"*",8,1. In his off time, he rides motorcycles and wrestles alligators (only one of those is true).