Scientists have integrated 2D materials a few atoms thick into a working memory chip for the first time and you can't tell me this isn't some prime Star Trek-level tech

Bring me the horizon. Or faster and more power-efficient chips, one of the two.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Every Friday

GamesRadar+

Your weekly update on everything you could ever want to know about the games you already love, games we know you're going to love in the near future, and tales from the communities that surround them.

Every Thursday

GTA 6 O'clock

Our special GTA 6 newsletter, with breaking news, insider info, and rumor analysis from the award-winning GTA 6 O'clock experts.

Every Friday

Knowledge

From the creators of Edge: A weekly videogame industry newsletter with analysis from expert writers, guidance from professionals, and insight into what's on the horizon.

Every Thursday

The Setup

Hardware nerds unite, sign up to our free tech newsletter for a weekly digest of the hottest new tech, the latest gadgets on the test bench, and much more.

Every Wednesday

Switch 2 Spotlight

Sign up to our new Switch 2 newsletter, where we bring you the latest talking points on Nintendo's new console each week, bring you up to date on the news, and recommend what games to play.

Every Saturday

The Watchlist

Subscribe for a weekly digest of the movie and TV news that matters, direct to your inbox. From first-look trailers, interviews, reviews and explainers, we've got you covered.

Once a month

SFX

Get sneak previews, exclusive competitions and details of special events each month!

Every now and then, I come across a tech development that makes me feel like I'm living in the future, and this is one of those moments. A team of scientists at Fudan University in Shanghai have published a study detailing their latest achievement, a fully functional memory chip built with integrated 2D materials a few atoms thick. Yesssss. This is the Star Trek-level technology I was promised as a child.

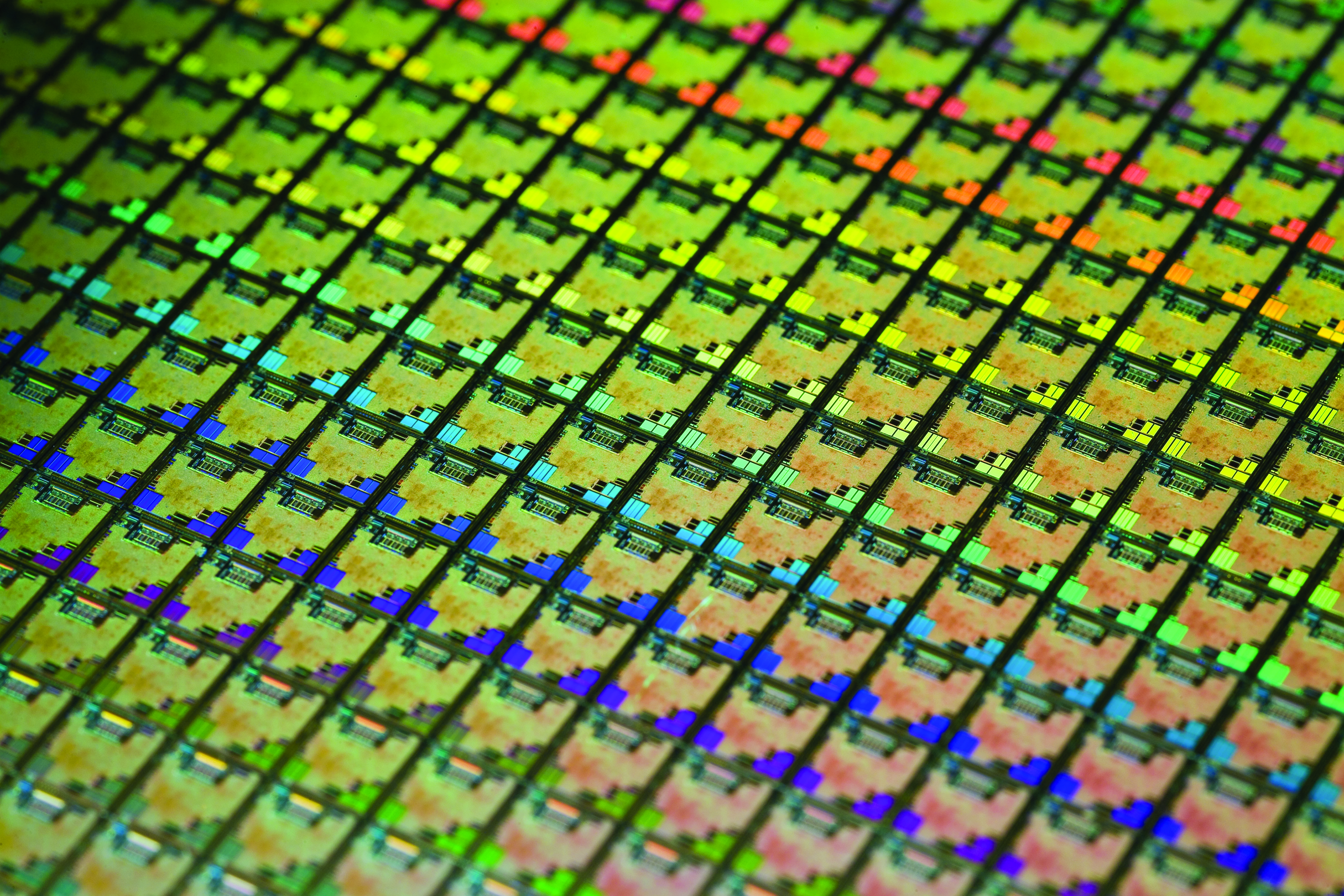

Well, maybe that's jumping the gun a bit. Still, the achievement here is incredibly impressive (via Tom's Hardware). Essentially, the researcher's new Atom2chip process allowed them to flow a layer of molybdenum disulphide, functioning as a memory array, on top of a 0.13 micrometre CMOS silicon chip—fusing together an emerging atomic-scale, "2D" technology with traditional methods to create a working hybrid memory chip.

The chip-riding 2D flash memory array is able to communicate with the CMOS chip's control logic via a custom interface, which in turn means that instruction-driven operations, 32-bit parallelism and random access instructions can be swapped between the two.

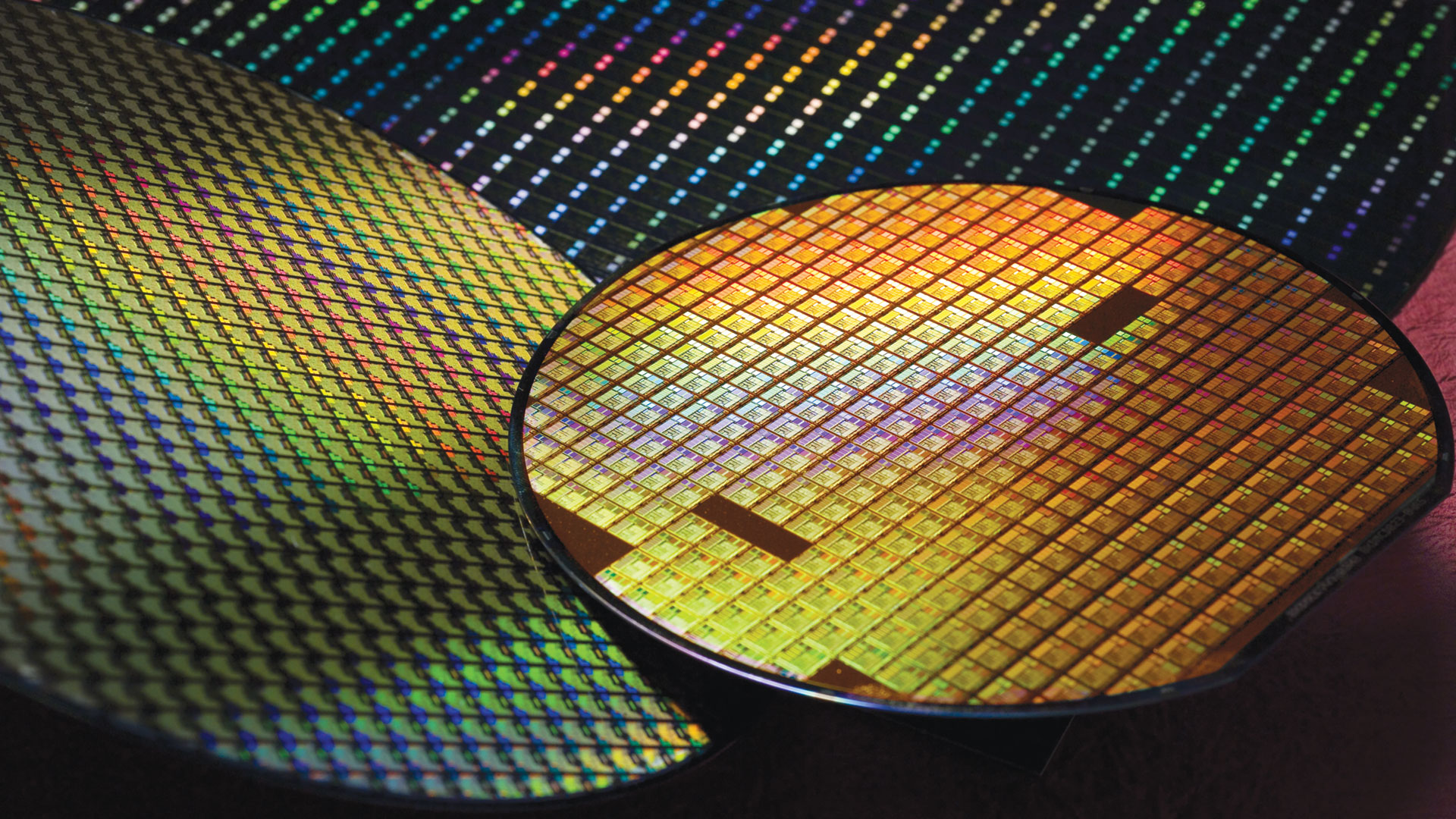

And the deeper you go, the more impressive the scale of the achievement becomes. While wafers are polished as part of the production process, they've still got a layer of uneven terrain (we're talking nano-level, here) that could otherwise tear a several-atom-thick layer into an unworkable mess.

The researchers had to develop a conformal adhesion process that allows the 2D material to flow and bond with the rough surface of conventional silicon to create their hybrid sci-fi chip, a mind-boggling thing in its own right.

The end result of this incredibly clever method is a memory chip with a five megahertz peak operating speed but an incredibly low power draw, with each bit said to consume just 0.644 picojoules of juice. Not only that, but the process appears to result in a very stable output, with a reported success rate of 94.34%. A mass-manufacturing method in waiting, then? Perhaps.

Up until now, two-dimensional materials have been demonstrated in individual lab experiments, not in working components that could potentially scale to meet demand. And as our conventional chip production methods become ever more difficult as the processes become smaller and smaller, 2D materials might be the key to stretching Moore's Law all the way down to the atomic limit in the decades to come.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

So, the upshot is, your CPU in the next few decades (I'm guessing here) might well make use of this very process in order to up the transistor density, all the while delivering massive power savings compared to the chips of today. Pie in the sky? Up until now, perhaps, but it's breakthroughs like this that could lead to it all becoming a reality.

Now, where's my Starship Enterprise? Still under development? Fine. Denser, more power-efficient chips thanks to nanoscale tech within my lifetime, though? Sure, I'll take it.

1. Best CPU: AMD Ryzen 7 9800X3D

2. Best motherboard: MSI MAG X870 Tomahawk WiFi

3. Best RAM: G.Skill Trident Z5 RGB 32 GB DDR5-7200

4. Best SSD: WD_Black SN7100

5. Best graphics card: AMD Radeon RX 9070

Andy built his first gaming PC at the tender age of 12, when IDE cables were a thing and high resolution wasn't—and he hasn't stopped since. Now working as a hardware writer for PC Gamer, Andy spends his time jumping around the world attending product launches and trade shows, all the while reviewing every bit of PC gaming hardware he can get his hands on. You name it, if it's interesting hardware he'll write words about it, with opinions and everything.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.