Meet the overclocker who made delidding your CPU idiot-proof

Delidding was once only for extreme overclockers, but this tool makes it easy for anyone to drastically lower their CPU's temperature.

When I first heard about "delidding," the act of removing the protective housing of a CPU, I thought it was a risky move that only the most extreme overclockers would pull. That's definitely how it looked: Google delidding even today and you'll mostly see images of razor blades next to gored CPUs, and find old forum testimonials about how to slice a processor in two without breaking it in the process.

The end goal is simple enough: if you open the CPU successfully, you can replace the thermal compound with something better, lowering your CPU temperature dramatically. It seemed like an arcane art, and for a long time it was; who puts their CPU in a vice and hacks into it with a razor? But in the past year, delidding has gone through a quiet revolution in the hardcore overclocking community, largely thanks to the invention of engineer and pro overclocker Roman Hartung, aka der8auer.

"When Intel started using polymer [thermal interface material] for Ivy Bridge and Haswell, I used a razor blade myself [to delid] and I damaged a CPU," Hartung says. "I'm like, fuck. 300 Euro were gone, and I was like, holy fuck, why is there not an easier way? So I was like okay, maybe I can find a way to do it. I made the very first delid tool about two and a half years ago. I even have a European patent for this."

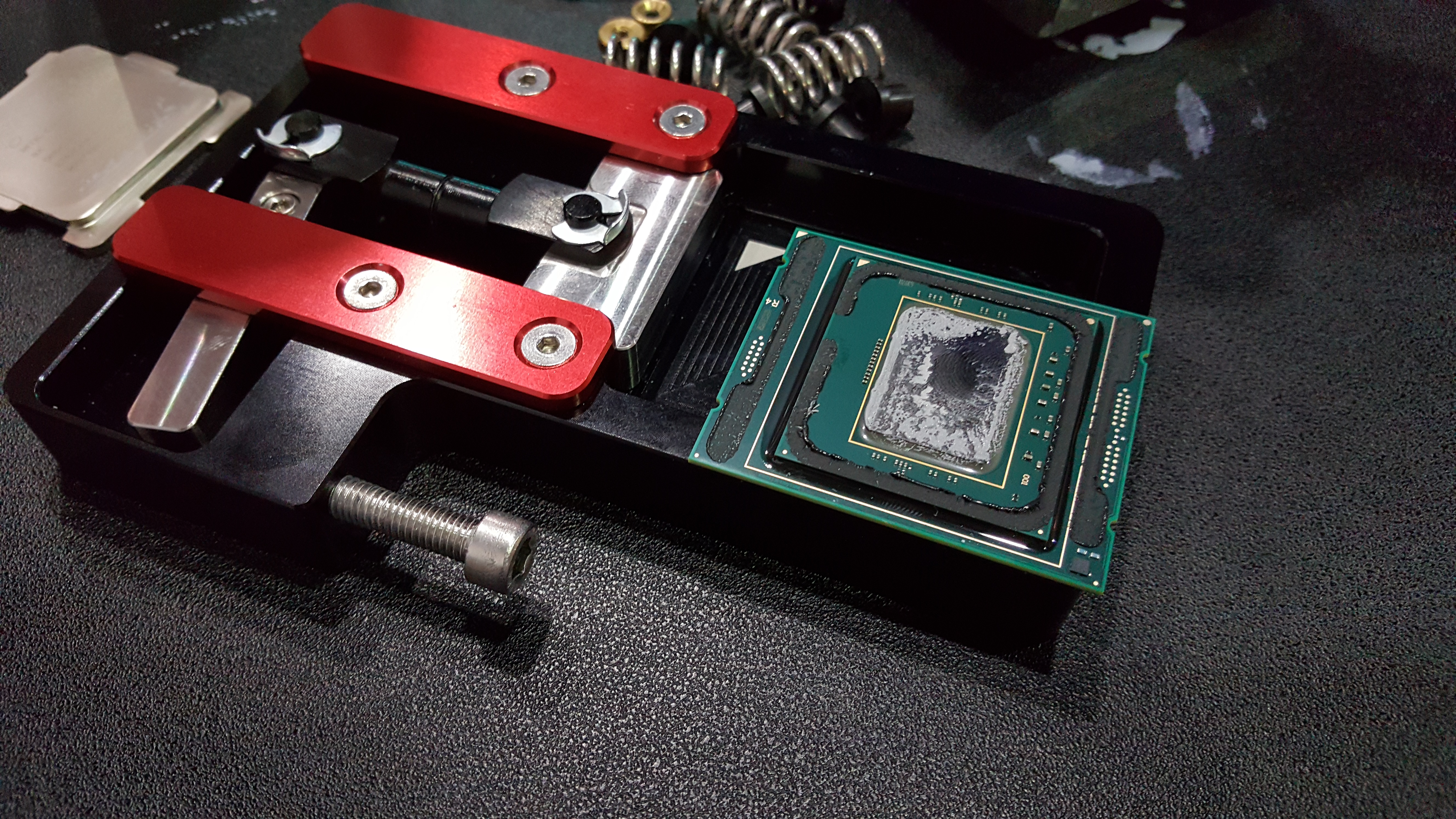

Hartung shows me the Delid-Die-Mate 2, which the German store he works for, Caseking, sells online. It's the second iteration of the design he did back in 2015. "The first one was a little bit more complicated design and manufacturing-wise," he says. "This is trimmed to be as user-friendly as possible and as cheap as possible. You can buy it for 30 Euro, which is fairly cheap, considering you buy the CPU for, say, 300. It's 100 percent safe delidding. It's impossible to kill your CPU with this."

Hartung is on break from competing on the overclocker's stage at G.Skill's Computex booth, where $10,000 is on the line. He's no stranger to the overclocking community, or to Intel. With a proud grin he tells me that after Caseking started selling the Delid-Die-Mate, Intel bought 10 of them. The tool has been revolutionary in making delidding both safe and easy.

It really is shockingly simple. You place your CPU in the Delid-Die-Mate's housing, slot in the slider above the CPU, and start cranking it with a hex key. The CPU's heat spreader will pop off after only a few rotations.

The only way you could damage your CPU? Put it in the Die-Mate in the wrong direction. But as long as you match the CPU's corner arrow to the Die-Mate's, you're golden. Since Hartung created the Delid-Die-Mate, a cottage industry of delidding tools has popped up. There are 3D print instructions out there to create your own, and a Kickstarter for a very similar tool called the Rockit88, which now sells online for $30. It was like a lightbulb went off: oh, delidding doesn't have to be insanely dangerous.

Keep up to date with the most important stories and the best deals, as picked by the PC Gamer team.

The Delid-Die-Mate 2 is consistently sold out. Caseking initially produced 2500, and every one sold out in pre-order before the manufacturing run was complete. Delidding may still be a niche interest for PC hobbyists, but there's clearly a healthy demand. And with words like "100 percent safe" thrown around, that demand is likely going to continue growing.

Since Hartung created the Delid-Die-Mate, a cottage industry of delidding tools has popped up.

Part of the timing, Hartung explains, comes from the way Intel builds its CPUs. For several years the heatspreader was attached with solder, making it much more difficult and dangerous to remove.

"Back in say the Core 2 generation, socket 775, the heat spreader was attached with solder to the die," Hartung says. "The solder is not like tin solder. It's indium. Indium is a rare metal, it's quite expensive as well, and it's very hard to use. So the thing is, if you want to solder this, it's not like you can just put indium on there and attach the heat spreader. You have to treat the die first, and the treatment is like tin, gold, vanadium... metals you actually should save, so economically speaking it's a lot better not to solder. Back in those days, the power consumption of the CPU was really high, so to keep the temperature as low as possible, they used solder. There are other theories as to why Intel is not doing it anymore; my theory is that it's not necessary, so they don't do it."

Intel stopped soldering its mainstream CPUs with Ivy Bridge, instead using a simpler thermal material. That makes delidding an attractive proposition. You can take the heatspreader off your CPU, replace the thermal compound with a better material, and significantly lower your CPU temperature, with much less risk than you'd take delidding a soldered CPU.

For its "Extreme" enthusiast CPUs, Intel continued to use solder, but that's finally changed this year with Skylake-X and Kaby Lake-X. For the first time, Intel's switched to a thermal compound. And some people are not happy about it.

"People are hating on Intel so hard for not soldering," Hartung explains. I asked why, since, as we discussed, the thermal material makes the CPU far easier to delid. His understanding? People look at it as Intel cheaping out. "They're like, 'what is this shit, I pay $2,000 and I get this crappy thermal paste?' They're really hating on Intel."

But from his perspective, it makes sense. "I'm not looking at it as a consumer. From the technical aspect, it makes so much more sense to use thermal paste. For the average gamer that doesn't really overclock that much, it doesn't matter whatsoever. If his CPU is running at 60 degrees or 65, it doesn't matter. And also, let's say they produce one million Skylake-X CPUs, which is absolutely possible. And they save, my estimate, like $3-$5 per CPU. The solder sheet is very expensive, and then you have to do all this layering stuff. So that means you already save $5 million just by not doing it. And you have lower RMA rates. From a company point of view, I cannot say anything negative about it."

No solder is a boon to delidding, which will allow dedicated overclockers the opportunity to eke more performance out of Skylake-X and Kaby Lake-X than any previous Extreme chip.

He does get the complaint that when you switch away from the better thermal conductivity of the solder, you lose a little bit of overclocking headroom: maybe 100-200MHz. If you're spending more than $1,000 on a CPU, maybe that's good reason to complain. On the flip side, no solder is a boon to delidding, which will allow dedicated overclockers the opportunity to eke more performance out of Skylake-X and Kaby Lake-X than any previous Extreme chip.

Naturally, Hartung's been figuring out how to delid them himself.

"Over half a year ago… I knew that Skylake-X was going to have conventional paste, so I started thinking of how can I delid Skylake-X," he says. "It's quite complicated. If you look at the CPU itself, you can see that there are a lot of components around the die. You have those very tiny SMD resistors here and here. It's very important the direction you're pushing. I had to figure that out first."

At Computex Hartung has a prototype he designed for delidding these new chips, but it's not quite perfect yet. The mechanism for pushing off the lid exerts so much pressure, one of the bolts in his new tool will eventually break. He needs to swap it out for a bigger bolt. He also needs to perfect a failsafe mechanism to keep you from pushing the heat spreader too far, which could end up scraping off some of the CPU's delicate components.

"I want to have it right at the launch of Skylake-X when it comes to the stores, but I can't promise that. It's very difficult. I really don't want anybody to ruin their chips. I don't want to do a safe delidding tool and then they kill their CPU. That's not what should happen."

So far, Hartung's new delidder is limited to working with the 10-core and below Skylake-X and Kaby Lake-X CPUS. The 12-18 core models have larger dies, pushing their other components to the edges of the PCB, and to date he's found it impossible to safely delid them. "I've been trying for like half a year to do the 12 core, but so far no luck. Killed too many CPUs," he says with a laugh.

The 10-core and below models, though? So far, so good. He estimates they've delidded 50-100 CPUs with the prototype, and every single one is still alive.

If you, like me, have been fretting over the temperatures of your Kaby Lake i7-7700K, Intel's response to overclockers—stop overclocking—probably wasn't what you wanted to hear. So before you assume a bigger, louder CPU cooler is your only recourse, think about delidding. It's a brave new world. Just don't use a razor.

Wes has been covering games and hardware for more than 10 years, first at tech sites like The Wirecutter and Tested before joining the PC Gamer team in 2014. Wes plays a little bit of everything, but he'll always jump at the chance to cover emulation and Japanese games.

When he's not obsessively optimizing and re-optimizing a tangle of conveyor belts in Satisfactory (it's really becoming a problem), he's probably playing a 20-year-old Final Fantasy or some opaque ASCII roguelike. With a focus on writing and editing features, he seeks out personal stories and in-depth histories from the corners of PC gaming and its niche communities. 50% pizza by volume (deep dish, to be specific).