How to Create Cool Custom Case Mods

Tenius2

Peter Husar is another accomplished case builder, as can be seen by his work at www.gtek-computerdesign.com/projects.html . Unlike Matwally, Husar’s tastes are geared towards the elegant and understated. His PC cases are literally works of art sculpted in fine varnished walnut and hand-brushed, black hard anodized aluminium.

Husar’s Tenius2 fits this mold. On the outside, Tenius2 appears to be a tall (2.5 feet), impossibly thin case that could sit discreetly beside a desk, or serve as a media center. Yet it can be packed with a decent amount of firepower. Tenius2's case can hold a Thin-ITX motherboard, a range of CPUs from i3 to i7 with up to 16GB RAM, a dedicated sound card (or TV tuner), an SSD, a full-size HDD and a Blu-ray/DVD optical drive. The motherboard is attached to Tenius2's black aluminum side (the other is aluminium with walnut attached to its exterior) to provide semi-passive cooling.

“The overall design of case was dictated by the components I was planning to use,” says Husar. “For example, the case is less than two inches thick, because it was designed specifically for an Intel Thin-ITX motherboard and Intel cooling solution.”

Husar made the Tenius2 case out of aluminum sheeting. “It's relatively easy to work with, even with a few basic tools like a bench drill, jig saw, tapping kit and screw drives,” he says. “As well aluminum is durable, strong enough for something like a PC case and can be painted easily.”

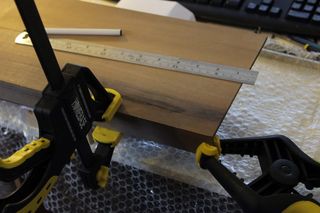

To get the dimensions right. Peter Husar laid out his components on a large measuring square. Using the dimensions he found there, Husar determined the size and shape of case parts he needed to cut from the aluminum sheeting.

“The next stage was manufacturing all of the aluminium parts,” he says. “The easier ones I had laser-cut. The more complicated parts I cut out, machined, drilled and tapped by myself.” Husar tapped (drilled holes into) the case so that he could countersink the screws flush with its exterior surface; both to assemble it cleanly and attach the components on the inside. (The only visible exterior screws are on the back of the case.) He also sanded and brushed the aluminum, before sending them to a finishing shop for black anodizing.

As for the wood? “I bought all of the walnut panels at the right thickness, so I just cut them to sizes I needed, glued them together using high adhesion glue, then sanded them down and finished the walnut with seven layers of clear satin wood lacquer,” says Husar. The finished wood shell was then glued to the appropriate aluminum side panel.

PC Gamer Newsletter

Sign up to get the best content of the week, and great gaming deals, as picked by the editors.

The other side panel serves as the plate onto which all components are bolted. Husar attached the CPU cooler directly to the side panel, adding lots of thermal paste to draw as much heat from the CPU and into the case for passive heat dissipation. Husar also reworked the CPU’s blower so that it blows heat out of the case. “I covered the blower with a custom-made cover to create low pressure chamber, which forces air through the heat sink and out,” he says. “The whole set-up resulted in absolutely quiet operation even under full load.”

Because he built his case using actual component measurements and layout, Peter Husar had a simple and easy assembly process. Once everything was in place, he hit the ‘On’ button and Tenius2 fired up without a hitch. Loading the O/S and software went without any serious problems. Today, his first Tenius2 runs at 62 C at full load, without any issues.

Click the next page to read about the Cor Leonis.

Alan has been writing about PC tech since before 3D graphics cards existed, and still vividly recalls having to fight with MS-DOS just to get games to load. He fondly remembers the killer combo of a Matrox Millenium and 3dfx Voodoo, and seeing Lara Croft in 3D for the first time. He's very glad hardware has advanced as much as it has though, and is particularly happy when putting the latest M.2 NVMe SSDs, AMD processors, and laptops through their paces. He has a long-lasting Magic: The Gathering obsession but limits this to MTG Arena these days.

Most Popular